“General Manager Zhang, another batch of goods has been returned by clients! They reported water leakage during outdoor rainy use!” The quality inspection manager’s report made me frown deeply. This was already the eighth waterproof quality complaint received this month.

As a trading company, product quality issues have always been our biggest pain point. Our previous flashlight factory always promised waterproof performance standards, but problems frequently occurred during actual use, resulting in consistently high return rates that severely affected our business reputation.

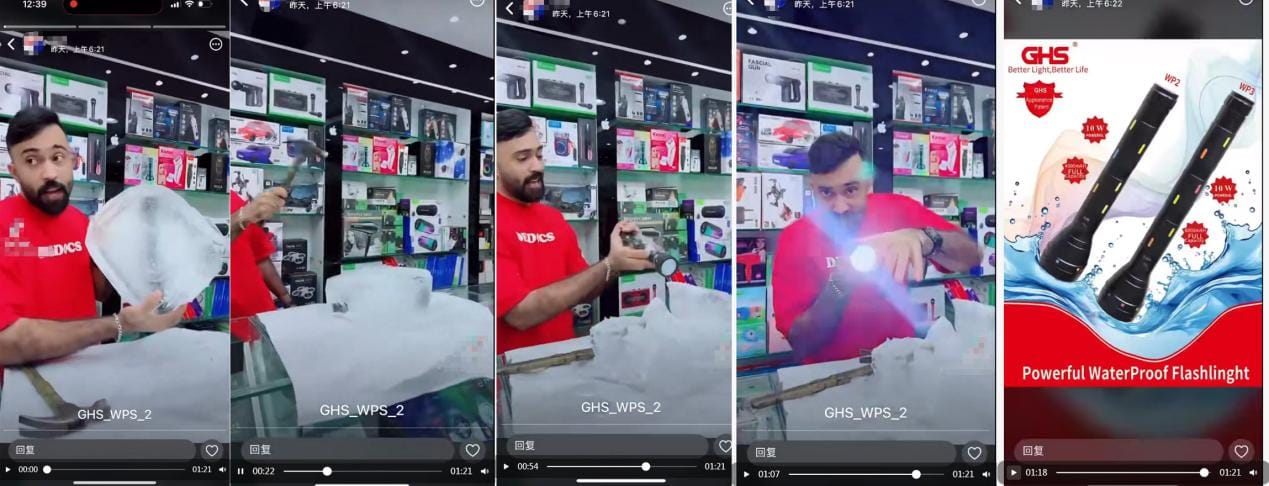

The Turning Point: A Viral Test Video

Just when I was at my wit’s end, our procurement specialist Xiao Liu excitedly rushed into the office: “General Manager Zhang, you have to see this video!”

Just when I was at my wit’s end, our procurement specialist Xiao Liu excitedly rushed into the office: “General Manager Zhang, you have to see this video!”

In the video, an outdoor gear review influencer was conducting an extreme test. He completely submerged a GHS WP2 model flashlight in water, froze it at -20°C for 24 hours, then removed the ice-sealed flashlight and broke the ice with a hammer. Astonishingly, the retrieved flashlight was not only intact but immediately emitted a strong beam when switched on.

“My goodness! This is the most waterproof flashlight I’ve ever tested!” the influencer exclaimed excitedly in the video.

The Investigation: Visiting a Genuine Quality Factory

Deeply impressed, I immediately contacted the GHS flashlight factory. The next day, I visited their production base. Entering the modern workshop, the scene before me was eye-opening:

“We are a fully integrated flashlight factory,” Quality Director Wang proudly explained. “From raw materials to finished products, every stage is completed in our own factory. The WP2 model tested in the video is just one example of our product standards.”

“That influencer’s rapid freeze test is actually just one item in our routine quality inspection,” Director Wang said with a smile. “As a professional flashlight factory, we ensure every product undergoes strict testing.”

Quality: Quality is Our Lifeline

What convinced me even more was their quality data:

– Product return rates consistently maintained below 0.3%

– Customer satisfaction reaching 99.6%

“Precisely because we are a fully integrated flashlight factory, we can strictly control every production stage,” Director Wang stated confidently. “This is the foundation of our quality commitment.”

The Transformation: From Crisis to Opportunity

Now, after one year of collaboration with the GHS flashlight factory:

– Return rates dropped from 15% to 0.2%

– Customer complaint rates decreased by 96%

– Order volume grew by 80%

– Profit margins improved by 20%

It was gratifying that our largest German client proactively proposed a long-term supply agreement after testing GHS products. He said: “This is the most outstanding waterproof flashlight I’ve seen in my twenty-year career.”

Choosing the GHS flashlight factory made me deeply understand that in the highly competitive export field, finding a fully integrated factory that prioritizes quality and can withstand extreme testing means finding solid assurance for sustainable development. Such a partner can not only help solve immediate difficulties but also establish a solid foundation for long-term growth.

#FlashlightFactory #FullIndustryChain #ExtremeTesting #QualityAssurance

(This article is adapted from real trading experiences.)