“General Manager Wang, the return rate has risen again this month! Clients report that flashlights often fail after use in rainy weather!” The quality manager’s report immediately worried me. This was already the third consecutive month with return rates exceeding 15%, seriously endangering our brand reputation.

As an outdoor equipment trader, unstable product quality has always been our biggest pain point. Our previous strong light torch light factory always advertised “waterproof and shockproof” capabilities, but problems frequently occurred during actual use, leading to continuous customer complaints and persistently high return rates.

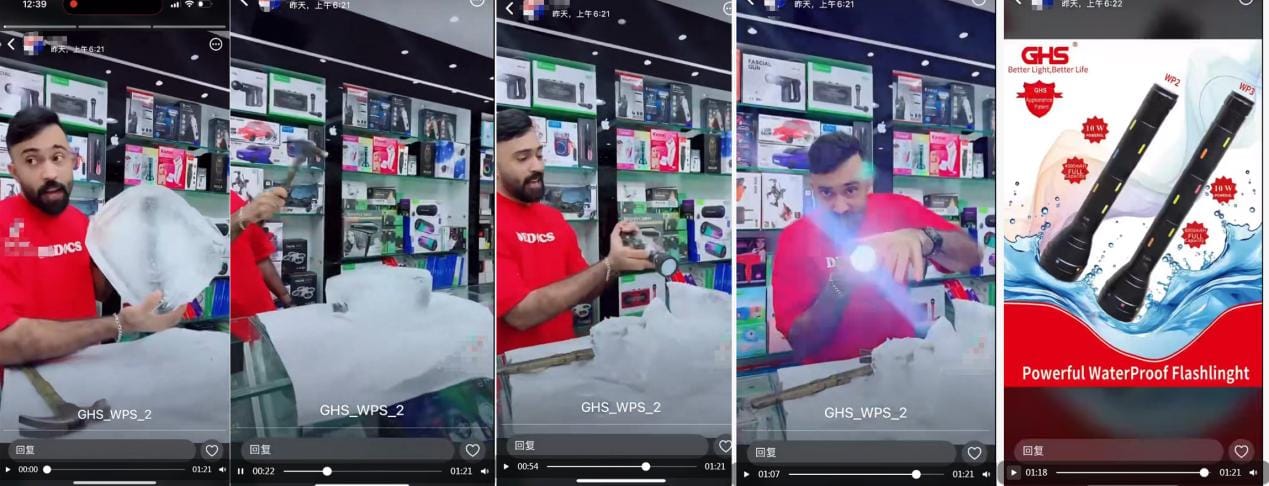

The Turning Point: A Viral Social Media Video

Just as I was considering abandoning this product line, our new intern Xiao Li rushed into the office: “General Manager Wang, you have to see this video! It’s already surpassed a million views!”

In the video, a well-known review influencer was conducting an astonishing test. He completely submerged a GHS WP2 model strong light torch light in water and rapidly froze it at -20°C for 24 hours. After 24 hours, he used a hammer to break the thick layer of ice. The retrieved torch light was not only intact in appearance but immediately illuminated the entire room with a 2000-lumen strong beam when switched on.

“Oh my! This is the most reliable strong light torch light I’ve ever tested!” the influencer exclaimed excitedly in the video. “The waterproof and freeze-proof performance exceeded my expectations!”

The Investigation: Visiting a Genuine Strong Light Torch Light Factory

Deeply impressed, I flew to the GHS strong light torch light factory the next day. Entering the production workshop, the modern production lines and strict quality inspection processes immediately caught my attention.

“We are a fully integrated strong light torch light factory,” Technical Director Chen proudly explained. “From LED chip selection to optical lens design, all core processes are completed in our own factory. The WP2 model tested in the video is just a glimpse of our product standards.”

“That influencer’s rapid freeze test is actually just one item in our routine quality inspection,” Director Chen said with a smile. “As a professional strong light torch light factory, we ensure every product passes corresponding quality tests.”

“That influencer’s rapid freeze test is actually just one item in our routine quality inspection,” Director Chen said with a smile. “As a professional strong light torch light factory, we ensure every product passes corresponding quality tests.”

Quality: Let the Data Speak

What convinced me even more was their quality data:

– Product return rates consistently maintained below 0.3%

– Customer satisfaction reaching 99.5%

“Precisely because we are a fully integrated strong light torch light factory, we can strictly control every production stage,” Director Chen stated confidently. “This is the foundation of our extended warranty promise.”

The Transformation: From Crisis to Opportunity

After one year of collaboration with the GHS strong light torch light factory:

– Return rates dropped from 18% to 0.2%

– Customer complaint rates decreased by 98%

– Order volume grew by 50%

– Profit margins improved by 20%

Even more exciting, our largest North American client immediately signed a three-year exclusive supply agreement after testing the WP2 model. The procurement director personally called: “This is the best-performing strong light torch light we’ve tested, with no exaggerated claims!”

Conclusion

Choosing the GHS strong light torch light factory made me deeply understand that in the highly competitive outdoor equipment market, finding a fully integrated factory that prioritizes quality and can withstand limit testing is equivalent to finding the golden key to sustainable development. Product quality is not just reflected in specifications but also in stable performance under extreme conditions. When a torch light can still function normally after being frozen for 24 hours, it conveys not just light but also a trustworthy quality commitment.

#StrongLightTorchLightFactory #FullIndustryChain #LimitTesting #QualityAssurance

(This article is adapted from real trading experiences.)